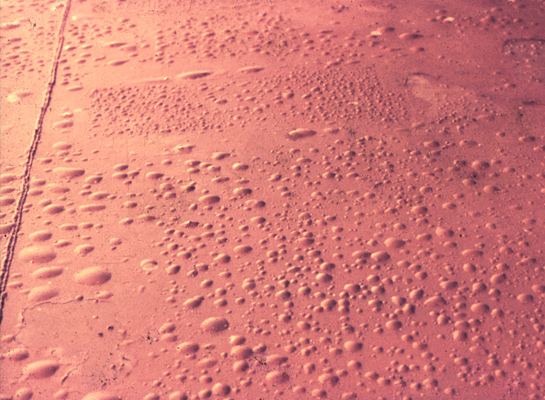

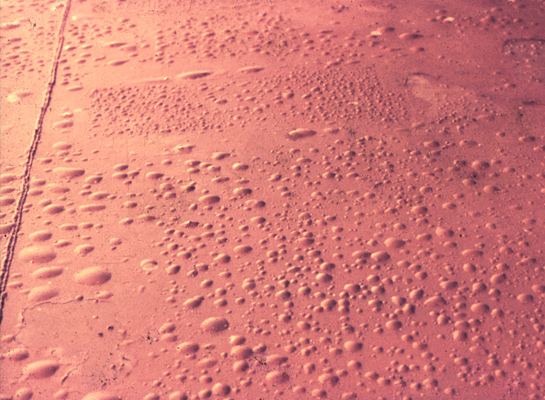

Blistering Defect in Coating

An unzipped carbon nanotube embedded graphene oxide membrane is reported. Soap test in channel cover with liner.

Fitz S Atlas Of Coating Defects And Surveys

The Company expressly warrants to the owner that for a period of ten 10 years the Warranty Period from the date of initial installation the Company will cover defects on ULTIMATE PLUS BLACK the Products such as.

. If container repairs total over 300 a new DD Form 2282 decal is required. The standards contained in this advisory circular AC relate to materials and methods used for the construction on airports. Film flakes off exposing the tablet surface.

The swelling is caused by the formation of an air bubble under the paint film due to the presence of moisture or oil or grease matter. Painted panels are shipped with a protective plastic sheeting or a strippable film coating between all panels. Re-inspection Rework of Manufactured Finished Good due to a possible defect in all or part of the BPN.

EfavirenzEmtricitabineTenofovir disoproxil is a fixed-dose combination of efavirenz emtricitabine and tenofovir disoproxil. This occurs when the coating fills in the lettering or logo on the tablet and is typically caused by improper application of the solution poor design of the tablet embossing high coating viscosity a high percentage of solids. Limited Product Warranty ULTIMATE PLUS BLACK PPF.

Loss of adhesion between the object and the electroplated coating is one of the most common types of electroplating failure. This website uses cookies to help provide you with the best possible online experience. Breaking News data opinions in business sports entertainment travel lifestyle plus much more.

Blistering and peeling are defects in which swelling of the paint film occurs. Remove any strippable film coating prior to installation and in any case do not allow the. Cracking blistering delaminating and discoloration.

A paper coating defect caused during the coating operation with an air-knife coater producing areas that are more transparent than the rest of the sheet. An improperly prepared surface will not allow the right final adhesion to happen between the object and the coating which can result in bubbling and blistering. Devices designed to harness this energy are known as fusion reactors.

Durable hydrophobic materials have attracted considerable interest in the last century. It is a defect best described as whitish specks or haziness in the film. The film becomes detached from substrate forming a blister.

The bubble will be developed if there was any welding defect such as crack pinhole etc. Entrapment of gases or vapor in or under the film due to overheating either during spraying or. Frequently in the coating industry the terms blistering and bubbling are used synonymously.

It is a coating defect where the film becomes detached from the substrate forming a blister. Blistering Coated Paper Caused when water vapours can not escape fast enough through coating layers in the coating dryer section of the heat-set press. They show remarkable water permeability and selectivity when this combination of graphene oxide and unzipped carbon nanotubes was used.

Currently the most popular strategy to achieve hydrophobic coating durability is through the combination of. It is a defect where the coating becomes dull immediately or after prolonged storage at high temperatures. Include but are not limited to.

Inspection repair alteration and reconstruction of steel aboveground storage tanks used in the petrochemical industry Training only Course Instructors. In most cases it is a result of the. It is a defect of film coating whereby volcanic-like craters appears exposing the tablet surface.

Research into fusion reactors began in the 1940s but to date no design has. Lifting lug weld joint. Handle hot silicone bags with a potholder or dry cloth to avoid burns.

A new DD Form 2282 decal is required when. One opinion is that if they remain unbroken they may not be considered a coating defect that requires. The multiwalled carbon nanotubes were longitudinally cut into multilayer graphene oxide nanoribbons by a modified Hummer method.

It is indicated for the treatment of human immunodeficiency virus-1 HIV-1 infection in adults aged 18 years and over with virologic suppression to HIV-1 RNA levels of 50 copiesml on their current combination antiretroviral. Please read our Terms Conditions and Privacy Policy for information about. A container is reinspected The existing 2282 has expired or is due to expire within 60 days.

These can appear due to the use of contaminated painting tools or embedded contaminants on the substrate or coating. Avoid over-filling bags with too much liquid for freezing to ensure the seal does not stretch or break. Technically this is not correct.

Hydrogen blistering inspection in hydrogen services hand lamp procedure Heat exchanger support steel structure foundation bolt and nut inspection. Proper spray booth air filtration and the contaminant elimination. Exposure to wet conditions can cause paint blistering and galvanized substrate corrosion or staining in as little as 2 weeks.

Our Advanced Materials are performance material solutions and epoxies that fulfil needs across critical industries globally. A container with a major defect cannot be used until the defect has been repaired and the container passes reinspection. Machine start up and cleaning of a typical tablet Blistering machine and the Cartoner for tablet packing.

Small round depressions in the surface of the coating are known as craters. When blisters form by an osmotic mechanism the term blistering is more common and correct. Backed with strong research and development the offerings address various touch points across the value chain in industries as diverse as construction coating composite and electrical applications.

Get practical pet health tips articles and insights from our veterinary community delivered weekly to your inbox. Causes and Remedies of Blistering. Bristle Marks Coated Paper.

Use care when opening hot silicone bags as steam can escape and burn. Fusion power is a proposed form of power generation that would generate electricity by using heat from nuclear fusion reactionsIn a fusion process two lighter atomic nuclei combine to form a heavier nucleus while releasing energy. Subscribe to PetMDs Newsletter.

When a thin layer of paint is coating on a glossy and smooth surface the paint may run back and sometimes leaves small areas of. To prevent staining and blistering avoid overheating of high-fat foods sugar oils and tomato sauce. Weighing sieving mixing granulating drying milling tabletting coating and printing.

Cladding and coating soundness. Use clean tools and water or solvents for painting the walls.

Osmotic Blistering An Overview Sciencedirect Topics

Blistering Failure Of Elastic Coatings With Applications To Corrosion Resistance Soft Matter Rsc Publishing Doi 10 1039 D1sm00986a

Comments

Post a Comment